MIG Welding: An Overview and Guide

April 28, 2022

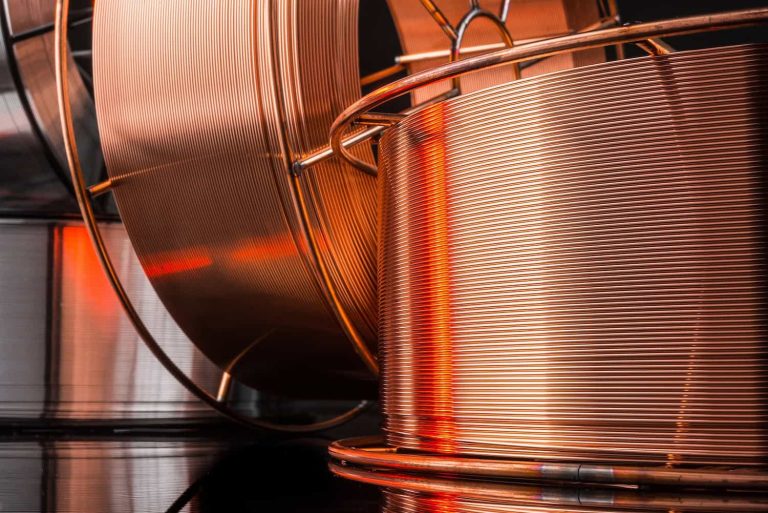

Metal Inert Gas (MIG) welding, also known as gas metal arc welding (GMAW), is widely considered to be one of the easiest welding processes to learn. The process was patented in 1949 primarily for welding aluminum. It has now expanded and is used for almost all types of metals such as stainless steel, copper and carbon steel, to name a few.

With the welder using a MIG welding gun and wearing the right protective gear to protect the hands and eyes from the high heat and bright light of the welding arc, even the novice welder can quickly learn how to fuse together two pieces of metal. The resulting weld may not be perfect, but it will come pretty close to it!

Overview of MIG Welding

MIG welding is a type of arc welding where a consumable wire electrode and an inert gas, also called a shielding gas, are fed through the welding gun. An arc is struck between the end of the wire electrode and the workpiece. A short circuit is created which produces an intense heat. The heat melts the metal pieces, allowing them to mix together and then fuse as the metal cools.

The purpose of the shielding gas is to protect the weld pool from reacting to atmospheric elements, like oxygen. The gas also affects the stability of the arc and the transfer of the metal. Gasses used in MIG welding depend on the metal that is being welded, but the most common ones are argon, carbon dioxide, and oxygen.

As with any welding process, there are advantages and disadvantages to MIG welding.

Advantages of MIG welding:

- Easy to learn.

- A number of different alloys can be used as well as combination metals.

- Can join metals of thin and medium thickness.

- Creates a good weld bead.

- High quality weld and very little splatter

- Lesser amounts of welding fumes are produced.

Disadvantages of MIG welding:

- Inert gas makes it less portable.

- Needs to be used inside since even a small amount of wind impacts the welding process.

- A bottle of gas is always needed.

- More sensitive to surface contaminants

MIG Welding for Beginners

MIG welding is the easiest for beginners to learn and the process that is the most forgiving of mistakes. The beginning welder, who may be using the MIG welder for home projects, needs to keep in mind:

- The metals must be thoroughly cleaned before trying to weld them together.

- Protective gear is essential!

- Be completely familiar with the MIG welder before attempting to use it.

- With the MIG welder, the power source controls the rate the wire is fed through the welder and the length of the arc. The welder manually controls the speed of travel and the position of the wire.

Most Common Industries Using MIG Welding

A welder who becomes proficient with MIG welding may find employment in one of the three main industries that use this process.

The Automotive Industry

The ability of MIG welding to make strong welds between very thin metals makes it an ideal process for the manufacturing of bicycles, automobiles, boats, and other vehicles. It works well for both the inside and outside body of any automotive product.

Also, aluminum is a metal of choice used in much of the automobile industry, and MIG welding was developed and patented originally for welding aluminum.

The Construction Industry

Steel is the most common metal used in the construction industry. It is used for everything from constructing gas and water pipes to building bridges. MIG welding has now become the welding process of choice for welding structural steel.

High Production Manufacturing

High production manufacturing refers to things like computer components, ship and auto parts, office equipment, and even home furniture. These types of items use metal that is conducive to MIG welding. In addition, the quick and cost-effectiveness of MIG welding makes it the welding process of choice for this industry.

Whether you are interested in welding for your own personal around-the-home welding projects, or in learning to weld as a career option, learning all you can about MIG welding is a good starting place.

Vern Lewis Welding Supply, Inc. Can Help

Vern Lewis Welding Supply, Inc. offers welding supplies, equipment, repairs, maintenance, welding classes, training, and more. Contact us for more information and to see how we can specifically help you meet your welding needs.

Sources:

- https://weldingheadquarters.com/what-is-mig-welding/

- https://www.tws.edu/blog/welding/what-is-the-easiest-welding-to-learn/

- https://usaweld.com/blogs/articles/learn-to-mig-weld-in-a-flash

- https://www.tws.edu/blog/welding/3-most-common-industries-for-mig-welding/#:~:text=MIG%20welding%20is%20most%20commonly,or%20interior%20of%20any%20vehicle

Join Our Newsletter

Sign up for our newsletter to receive specials offers, product updates, and more!