On May 10, 1869 in Promontory Summit, Utah, more than 1,000 people gathered to watch the president of the Central Pacific Railroad Company of California, Leland Standford, drive the Golden Spike. This was the last spike needed to complete the track for the transcontinental railroad, opening the railroad for business. Across the country, there were celebrations and parades to commemorate the accomplishment of this cross-country feat.

Prior to the completion of the transcontinental railroad, connecting the East Coast to the West Coast of the U.S., it took months of overland travel in often dangerous conditions to cross the country. Now, a person could hop on the train and cross the country in barely a week’s time.

Goods were transported rapidly by rail, even though initially there was only one train headed east and one headed west each week. Telegraph poles were installed along the side of the train tracks, increasing communication as well as transportation, across the U.S.

As for the railroad industry, the tracks were installed with clips or fasteners. They often buckled under the weight of the train and had to frequently be repaired. Eventually, the early rails of wood or cast iron were replaced with steel. It took a few years but the railroad industry found the advantages of welding the rails.

Types of Welding Used in the Railroad Industry

The welding of railroad track was first tried in the early 1930s, but it didn’t seem to work well. It wasn’t until the 1950s that welding lengths of the track became standard.

Rails are produced in lengths between 12.5 m to 100 m. They must then be welded to be one continuous rail of about one-quarter mile. Next, the quarter-mile rails are welded to become even longer continuous lengths. The long lengths of welded track make for a smoother track that actually requires less maintenance that the shorter tracks.

Four types of welding are used for railroads: 1) Gas pressure welding; 2) enclosed arc welding; 3) flash-butt welding; and 4) thermite welding. Although all types have their purpose, the two main types of welding most commonly used for railroads are thermite welding and flash-butt welding.

Thermite Welding. Thermite welding is considered the state-of-the-art welding process which creates a seemingly seamless rail when welding lengths of railroad track.

There are thirteen steps to implementing thermite welding. They can be broken down into three parts: preparation, operation, and inspection. If preparation is not thorough, there is a risk of foreign material being introduced and compromising the weld.

A simple overview of the process involves intense heat which requires the welder to wear appropriate protective gear.

Flash-butt welding. Flash-butt welding also uses intense heat. No filler is used, so there is no risk of foreign material compromising the weld. According to Trackopedia, modern welding robots can be programmed to work according to welding standards. This makes it possible for rail welds to be produced automatically and securely.

Role of a Welder Working in the Railroad Industry

Welders working for the railroad industry generally have the responsibility of maintaining the tracks along the train route. The welder is expected to identify tracks that need repair, assess the extent of the damage, and know what materials to order for the repair. They work in various weather conditions and sometimes travel to repair tracks distant from their home.

To become a railroad welder, you must have a high school diploma or your GED certificate. You must have some welding experience. It is possible to obtain an entry-level position that will give you on-the-job training. Completion of some formal welding training, perhaps a mix of classroom work and hands-on experience, is helpful.

Qualities you are expected to have are good communication skills, paying close attention to details, and always being aware of safety.

Consult With Vern Lewis Welding Supply For Welding Classes and Products

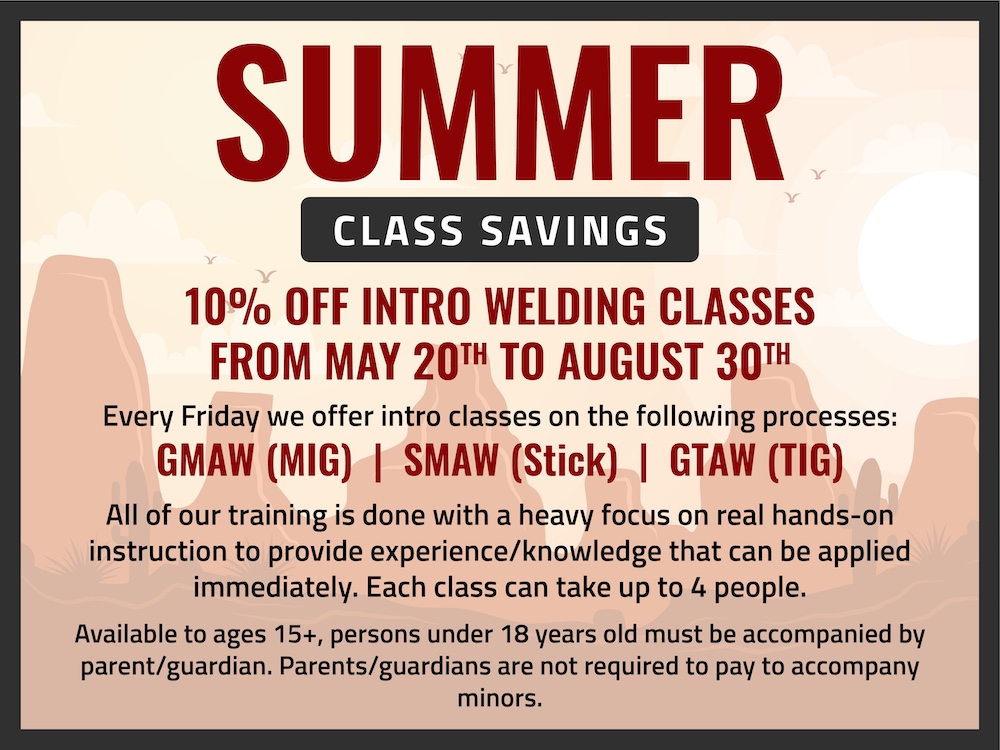

At Vern Lewis Welding Supply, we have a state-of-the-art training facility with experienced instructors. If you are a beginner and think becoming a welder is in your future, check in with us and take a class. Learn for yourself what a rewarding experience is to see your welding project come together.

We have eight locations in Arizona and have been helping welders with their projects for more than 50 years. You can find a Welding Supply location near you. Contact us for more information.

Sources:

- http://www.railway-fasteners.com/news/what-is-railroad-thermite-welding.html#:~:text=The%20railroad%20thermite%20welding%20is,of%20thermite%20welding%20is%20widespread.

- https://blog.mtiwelding.com/low-force-friction-welding-rail

- https://www.leonhard-weiss.ee/eng/portfolio/raudteed/raudtee-keevitus.html#:~:text=In%20order%20to%20ensure%20maximum,time%20is%20of%20great%20importance.

- https://www.millerwelds.com/resources/article-library/the-history-of-welding#:~:text=In%201903%2C%20a%20German%20named,during%20this%20period%20as%20well.