Welding Magnesium: Understanding the Basics

June 21, 2022

Magnesium is the most lightweight metal on earth and also one of the most abundant elements that can be found within our earth’s crust. Its strength to weight ratio makes it very useful for aerospace as well as race cars! An added bonus to this metal is that it remains corrosion free which means it can be used in a variety of applications.

Here are some general points to keep in mind about welding magnesium.

Magnesium Can Be a Difficult Metal to Weld

Magnesium can be tricky to work with so it may not be the common choice for most welders. The metal has a flashpoint of 833º F and easily catches on fire. It burns at a temperature of 4,000º F. Although difficult to work with, if the correct welding method is used and proper safety precautions followed, welding magnesium can be successful.

In the event of a magnesium fire, it can only be put out by starving it of oxygen or using a Class D fire extinguisher that is recommended by the U.S. Department of Labor Occupational Safety and Health Administration (OSHA).

Identify the Base Metal as Magnesium Before Beginning the Welding Process

It may seem like basic Welding 101 to identify the metal before beginning the welding process but this is particularly important when welding magnesium as it often times can be confused with aluminum. According to enineeringchoice.com, magnesium is rarely found in free form within nature as it is highly reactive. For this reason, you must know which magnesium alloys are present within your base metal. Common magnesium alloys include manganese, zirconium and zinc.

Identify Alloy Composition

It is also important to learn what alloy composition you are working with as varying alloys have different filler requirements. The best way to learn about this is to check with the manufacturer. If this is not possible, the American Welding Society has handbooks you can use to help with this identification.

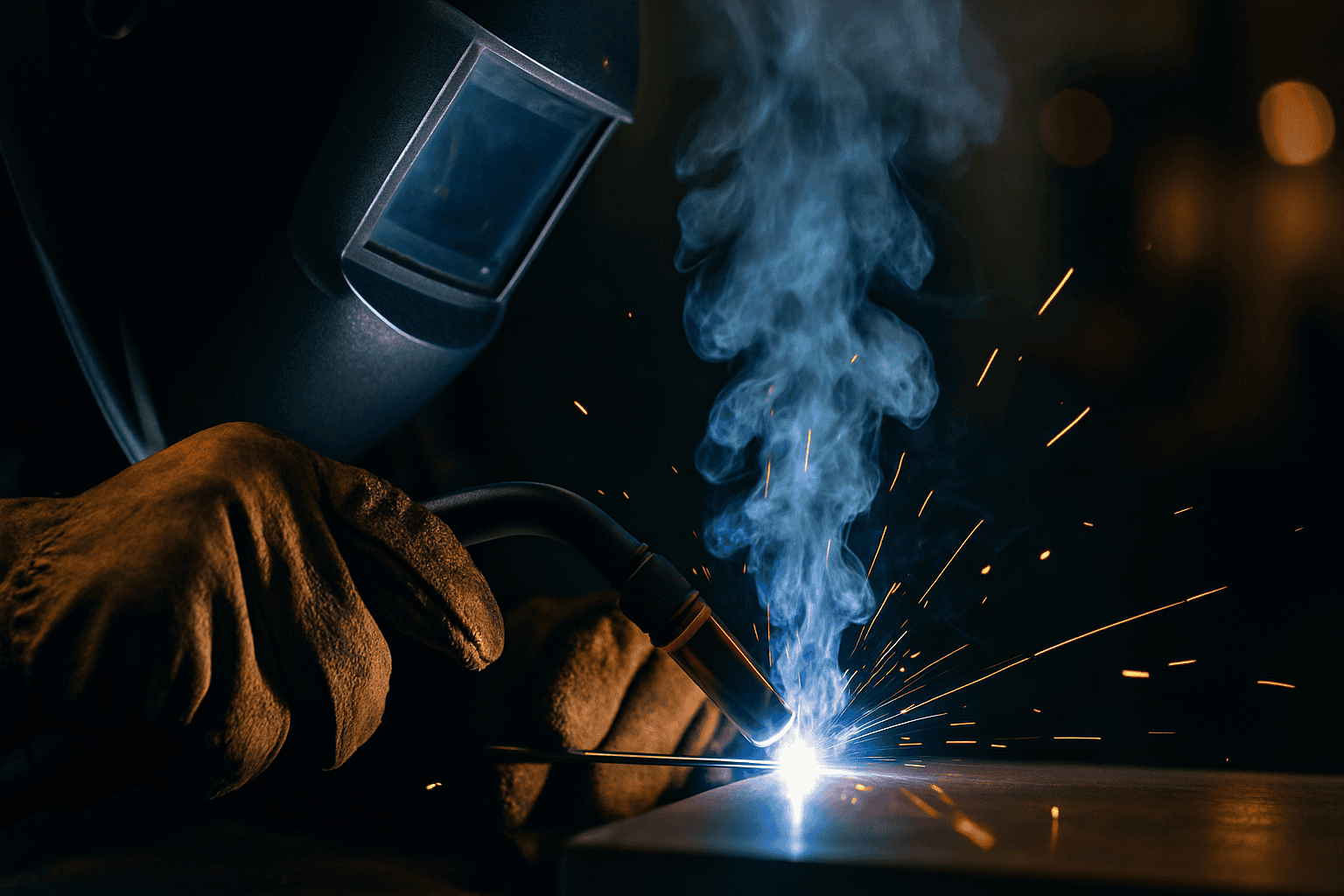

TIG Welding is Best for Magnesium

Although several types of welding processes can be used for welding magnesium, the ideal method is Tungsten Inert Gas (TIG) welding, which may also be known as Gas Tungsten Arc Welding (GTAW). It is a process invented in the 1940s specifically to be used for welding both magnesium and aluminum.

TIG welding is thought to be about the most difficult type of welding as it requires more coordination and practice than other forms of welding.

For example, a foot pedal is used to control the arc length while both hands remain busy. One supplies the sacrificial rod, and the other hand aims the electrode at the work surface. Again, always be aware of best safety practices as magnesium is a highly reactive metal. It may benefit the beginner welder to seek assistance from a peer when learning this method.

Contact Vern Lewis Welding Supply

Vern Lewis Welding Supply is happy to answer any questions you may have about welding magnesium. Our team of professionals are available to help you prepare for your next welding project! Contact one of our 8 locations today for more information.

Sources:

- https://investingnews.com/daily/resource-investing/critical-metals-investing/magnesium-investing/magnesium-the-other-bike-frame-metal/

- https://www.intechopen.com/chapters/37746

- https://www.totalmateria.com/Article35.htm

- https://weldingmastermind.com/how-to-tig-weld-magnesium/

- https://www.arc-zone.com/blog/joewelder/2013/07/02/tig-welding-in-the-u-s-a/

- https://weldingmastermind.com/what-tig-welding-is-used-for-how-to-know-when-to-use-it-%ef%bb%bf/

- https://www.engineeringchoice.com/magnesium-welding/#:~:text=Because%20magnesium%20is%20flammable%2C%20the,won’t%20cause%20a%20fire.

- https://www.thecrucible.org/guides/welding-2/learn-tig/

- https://www.aws.org/about/page/home

- https://www.corrotherm.co.uk/blog/the-lightest-metal-of-all-time-magnesium

- https://matmatch.com/learn/material/magnesium-alloys

Join Our Newsletter

Sign up for our newsletter to receive specials offers, product updates, and more!