Why Is Preheating or Post-Heating Sometimes Necessary in Welding?

November 3, 2025

When it comes to welding, success isn’t just about striking a clean arc — it’s about controlling what happens before and after the weld, too. That’s where preheating and post-heating come in.

They’re not just for special jobs or thick metals. In many cases, these temperature treatments can make the difference between a strong, reliable weld and one that’s brittle, cracked, or destined to fail.

In this post, we’ll break down why preheating and post-heating are sometimes necessary, when to use them, and how they help you produce better, longer-lasting welds.

What Is Preheating in Welding?

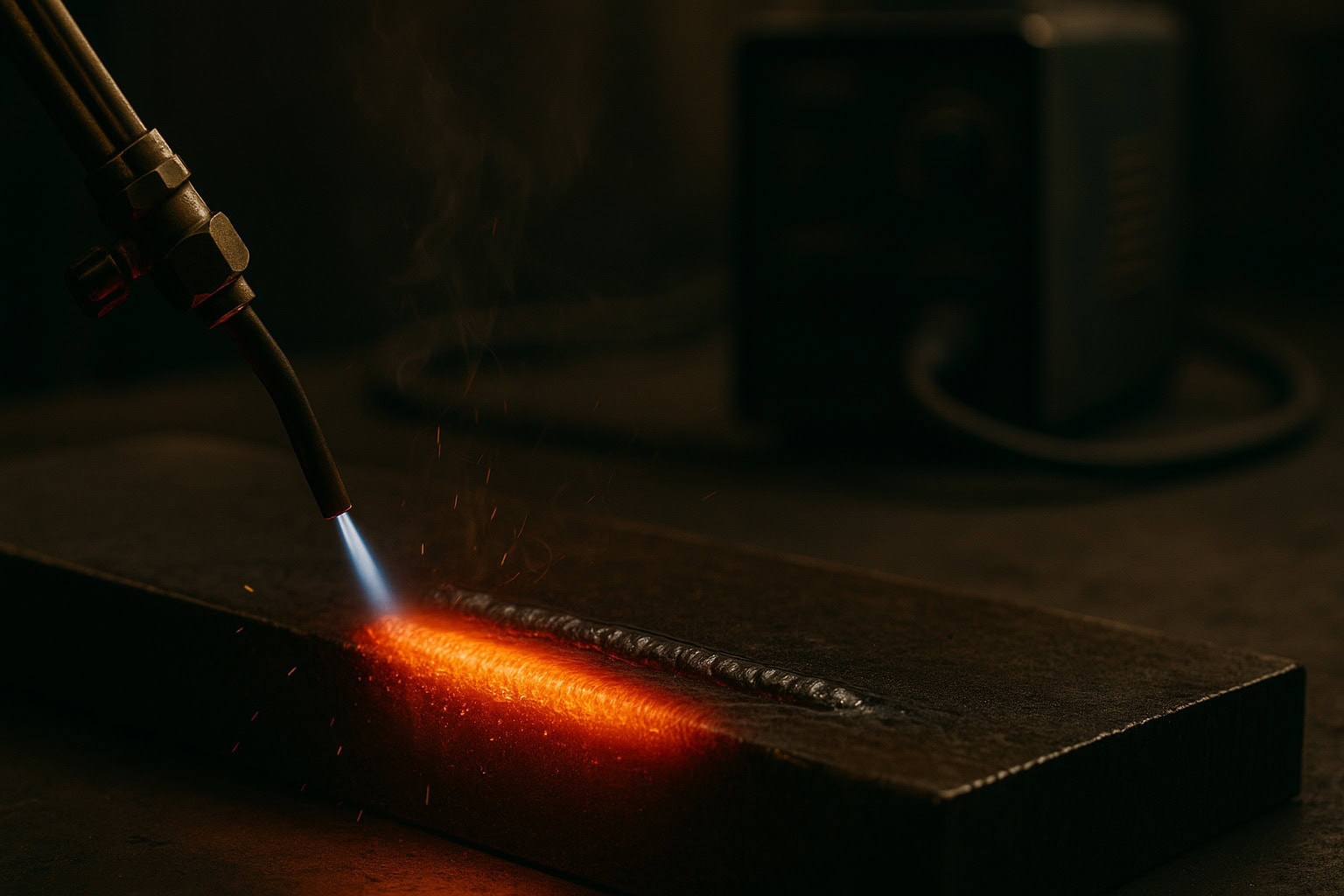

Preheating means raising the temperature of the base metal before you start welding. This is usually done with a torch, induction heater, or electric heating pad — just enough to warm the workpiece to a specific minimum temperature.

But why bother?

Here’s what preheating does:

- Slows the cooling rate after welding

- Reduces the risk of cracking, especially in carbon steels

- Drives off moisture that could otherwise lead to porosity or hydrogen cracking

- Minimizes thermal shock, especially in large or thick components

Preheating is especially important when working with:

- High-carbon or alloy steels

- Thick sections (usually over 1 inch)

- Parts with complex joints or restrained geometry

In short, it gives your weld the best chance at success by helping heat flow more evenly — and cool more slowly.

What Is Post-Heating (or Post-Weld Heat Treatment)?

Post-heating happens after welding — and its purpose depends on the material and the application.

There are two main types:

- Immediate post-heat (hydrogen bake-out): Keeps the weld hot right after welding to allow hydrogen to diffuse out of the metal and avoid cracking.

- Post-weld heat treatment (PWHT): A controlled process used to relieve residual stresses, reduce hardness, or improve toughness by holding the weld and base metal at a specific temperature for a certain amount of time.

Post-heating is commonly used in:

- Pressure vessels

- Pipelines

- Cast iron and hardened steels

- Critical structural components

It’s also often required by welding codes, especially when working under a WPS (Welding Procedure Specification).

Why Does Temperature Control Matter So Much?

Think of welding as controlled heating and cooling. If metal heats or cools too quickly, it changes at a molecular level. That’s where problems begin.

Without preheating or post-heating, you risk:

- Cracking (especially cold cracking in steels)

- Distortion

- Residual stress buildup

- Hard, brittle heat-affected zones (HAZ)

These issues aren’t always visible right away, but they can lead to costly failures later on — especially in high-pressure, high-load, or high-temperature environments.

By controlling temperature before and after the weld, you’re giving the metal time to “relax” — and that leads to a stronger, more stable weld.

When Should You Use Preheating or Post-Heating?

There’s no one-size-fits-all rule, but here are some common indicators that temperature control may be needed:

Use Preheating When:

- Welding high-carbon or alloy steels

- Working with thick sections or large parts

- The weld joint is highly restrained (can’t expand or move)

- Moisture or cold weather is a factor

Use Post-Heating or PWHT When:

- Required by code or spec (especially ASME, API, or AWS)

- Welding hardened or heat-treated steels

- Fabricating pressure-retaining components

- You need to reduce hardness or residual stress after welding

If you’re unsure, check the WPS for the project — or consult a knowledgeable welding supplier.

Practical Tips for Welders

Knowing when to use preheating or post-heating is important, but applying that knowledge on the job is what really counts. Here are some straightforward tips to help you manage heat more effectively and get better results from your welds.

- Use temperature crayons or digital thermometers to monitor preheat/postheat levels accurately.

- Avoid overheating — more is not always better. Stick to the recommended range.

- Even, uniform heating is key. Don’t just warm one side of the part.

- Keep the workpiece warm between passes, especially if working on large or multi-pass welds.

Conclusion: The Weld Starts Before the Arc

Preheating and post-heating may sound like extra steps, but they’re often essential — especially when working with tougher materials or high-stakes jobs. Think of them as part of your welding toolbox: not needed every time, but critical when the job calls for it. They help prevent cracking, improve durability, and give your welds a stronger foundation to stand on.

Need advice on preheating tools, temperature control gear, or when to use them? Stop by Vern Lewis Welding Supply. Our team can help you choose the right setup for your materials, process, and project needs.

Join Our Newsletter

Sign up for our newsletter to receive specials offers, product updates, and more!